After the economic challenges of the past decade, industrial companies realized an important

truism: It is becoming imperative to embrace digital to meet changing customer expectations

and respond to competitive threats.

Companies are feeling the pressure to determine how digital fits into their business models and

the right ways to leverage its myriad possibilities. They know a differentiated focus on sustainable

growth drives shareholder value, and that growth often comes from new technology and

improvements in speed to market. Providing top-level customer service is also a factor: People

have been greatly influenced by the convenience of digital offerings (Amazon, Apple and Uber,

to name a few), leading customers, as well as distributors, to expect certain digital experiences

in their daily routines.

The Internet of Things (IoT) — also known as machine-to-machine communication — has also

become increasingly prevalent. A growing number of devices — cars, thermostats, watches,

industrial equipment and more — have the ability to wirelessly communicate and share data

with one another. The IoT is also gaining attention from businesses, consumers and even

governments for its potential to drive efficiency,

unlock new business opportunities

and automate processes. It is quietly extending

the same types of opportunities — and

disruptions — the Internet brought to the

analog world. And this network of devices is

only growing: Some 30 billion objects could

be connected via the IoT within the next few

years, leading to incremental economic

growth that could exceed $11 trillion by 2025, according to a recent McKinsey study.

Over the past two years, Spencer Stuart has partnered with the Manufacturers Alliance for Productivity and Innovation (MAPI) — a network of leaders dedicated to building strong leadership

within industrial manufacturing — to study digital transformation trends in the sector.

Together, we surveyed 270 senior-level executives across the sector to learn what “digital”

means today, and where industrial companies stand on their digital journey. The result of our

effort finds a year-over-year acceleration of digital adoption and growth, and captures lessons

learned along the way.

Finding new opportunities — and new challenges

It’s clear that digital can be a catalyst for new avenues of growth. Nevertheless, many companies

have only recently begun thinking about how to enable a digital strategy.

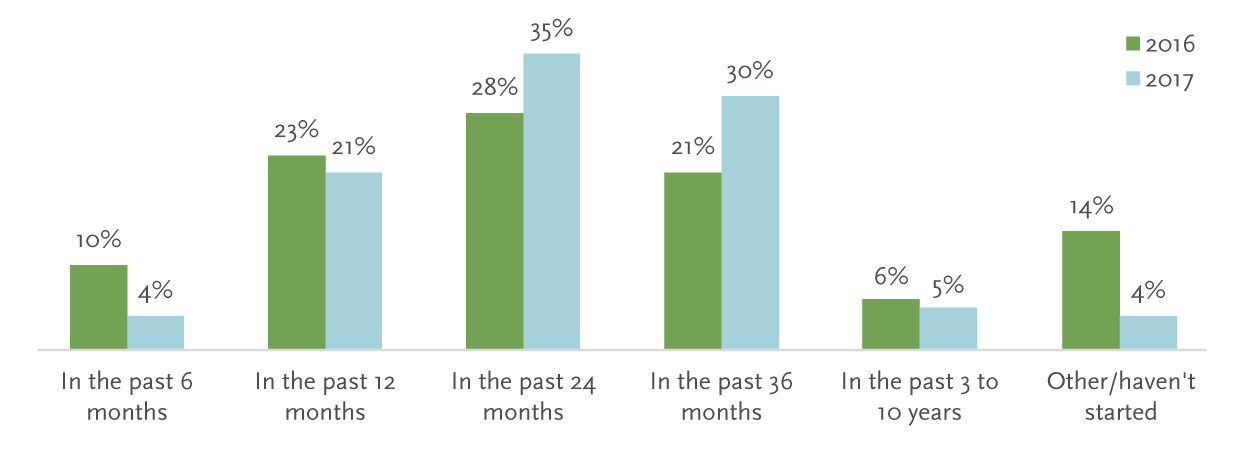

Acceleration of focus on digital transformation

When did your company start focusing on digital transformation?

The high-tech, consumer and financial sectors embraced digital technology years ago, and, as a

result, most individuals have been exposed to “digital experiences” in their personal lives (e.g.,

mobile banking and online ordering). Within the industrial sector, companies have differing views

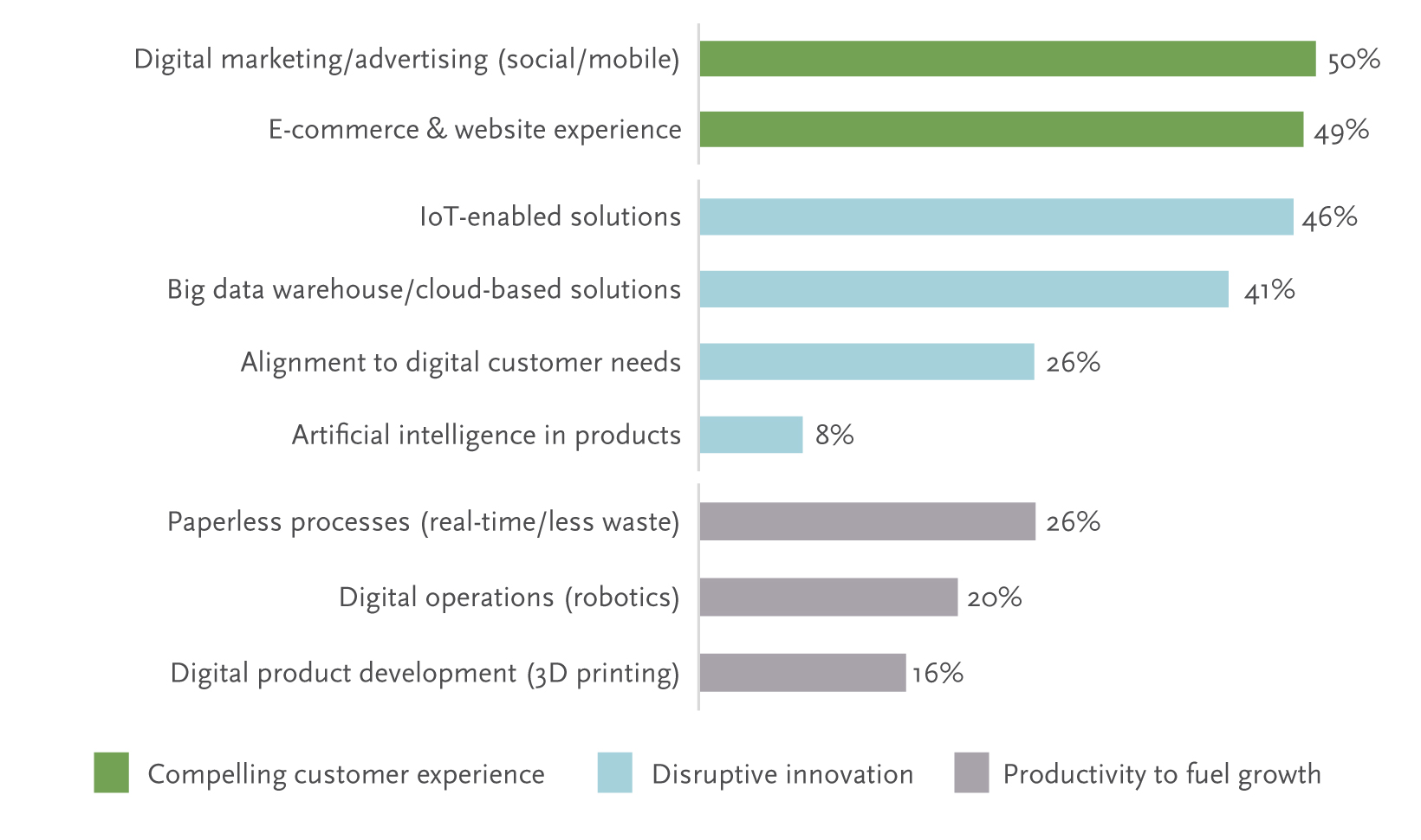

of what digital technology means for the business, generally falling into three categories:

-

Creating a compelling customer experience: Digital marketing is gaining popularity in

industrial businesses, and companies are rapidly building their online customer experience

through web-based technical support, e-commerce, social media and mobile

applications. Often, the talent with deep digital marketing experience comes from more

traditional consumer marketing sectors, such as banking, personal care products and

Silicon Valley companies.

- Disruptive innovation for incremental revenue: Embedding IoT technology into traditional

industrial products — such as sensors for predictive diagnostics, preventative maintenance

and cloud-based analytics — provides an opportunity for industrial companies to

reinvent their value propositions to their customers and create new services and databased

revenue streams.

- Productivity to fuel growth: The digitization of core internal processes — such as the

use of paperless processes, robotics, additive manufacturing and digital product development

— eliminates waste, freeing up time for more customer-focused activities while

also speeding time to market.

Industrial’s definition of digital

Changing the customer experience

A successful digital evolution requires the organization to place the customer at the center of its

digital strategy and to begin to think “outside-in,” industrial leaders said. Whether efforts have

an external or internal focus, the goal is to provide customers with a better user experience,

create new value for them and eliminate waste to serve them better.

The possibilities that digital presents are exciting, but the path to becoming digitally proficient

also brings many challenges. Integrating digital capabilities requires robust back-end business

capabilities (including analytics, IT development and security expertise), a strong focus on the

customer and the ability to work across functional and geographic silos.

When fully taken advantage of, these changes can be transformative. For example, Dematic, a

traditional supplier of material-handling equipment, set out to reinvent its value proposition by

embedding IoT and data analytics into its sensors along conveyor lines. The company used

these new capabilities to capture data on packages moving throughout the warehouse. By using

robust analytics, Dematic was then able to provide its customers with valuable recommendations

to optimize routing flow by eliminating bottlenecks. This digital technology shift

repositioned them from a product provider to a valuable supply chain optimization partner

through the ability to deliver performance and productivity improvement recommendations.

Dematic CEO Ulf Henriksson said his company looked at digital as a huge opportunity to redefine

the company’s value in the minds of its customers. “Many companies are waiting for IoT to

be defined before they take action and invest,” he said. “You have to define it yourself so you can

tie a solution to it.”

The digital revolution has also provided excellent customer marketing opportunities for manufacturing

companies. Digital channels, such as social media and an intuitive website enabled

with technical resources, allow companies to cultivate a personalized brand and stay front and

center with customers, which can help businesses avoid being disintermediated.

But creating a strong front-end digital marketing effort can also lead to unintended consequences,

such as the problem of being too successful. A company that makes itself accessible

through e-commerce could open its funnel too wide, leading to distribution challenges. When

launched, there’s an accelerated trickle-down impact from web-based marketing/sales through

the rest of an organization, and manufacturing and supply chain need to be prepared for the

increased demand, change in product mix and required delivery speed. Often, this leads a

company to upgrade its digitization back-end efforts, as well.

The use of robotics and other advanced manufacturing technologies can lead to quicker product

availability and improved cost of goods sold, but delivering them quickly to the customer raises

another issue. To meet customers’ e-commerce delivery expectations, producers may have to

establish new stocking locations near consumers and scale their distribution footprint.

“We call this the ‘tyranny of now,’” Henriksson said. “You and I — and especially our kids — want

things now. But not only does delivery have to be fast, it also must be predictable when we want it

at a specific time. These days, time is everyone’s greatest asset, and nobody wants to spend time

conforming our lives to shopping anymore. We want shopping to conform to us.”

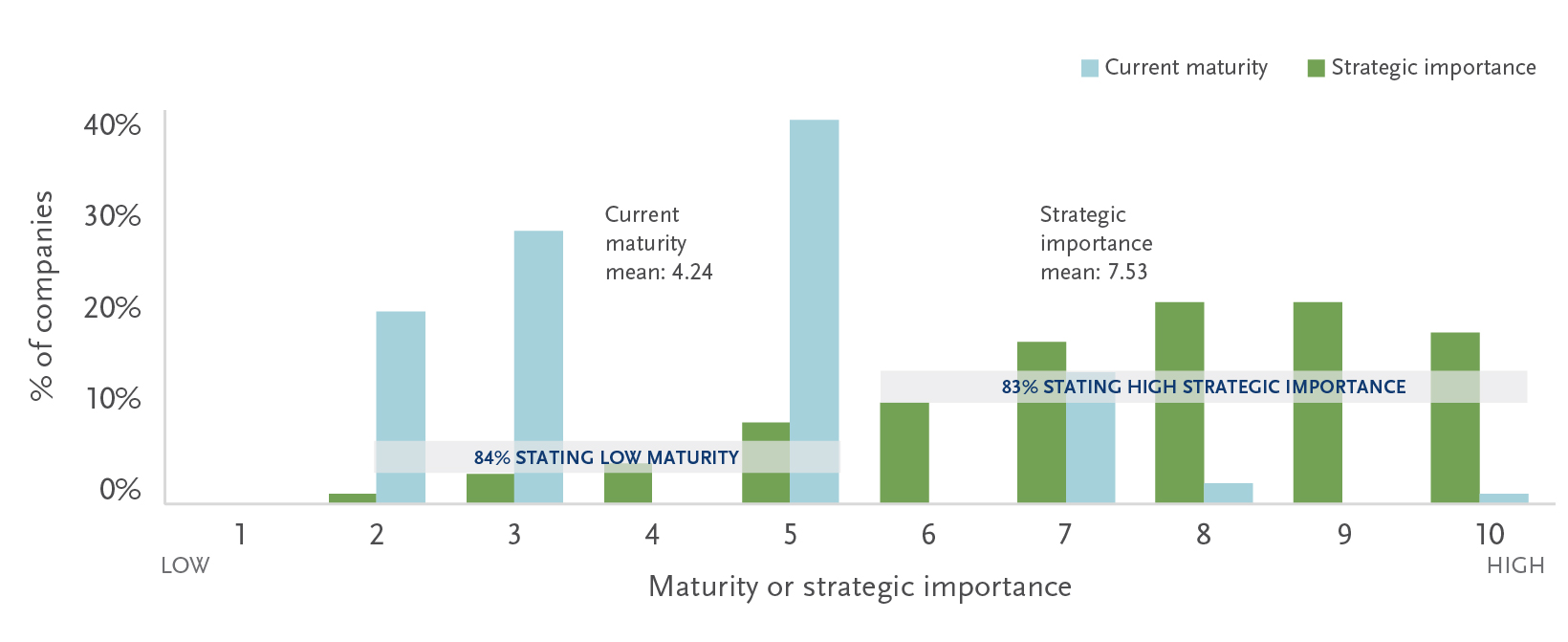

Digital's strategic importance and maturity

There is no doubt that industrial manufacturers are seeing the benefits of leveraging digital,

and adoption is underway. In our survey, 83 percent of respondents ranked digital transformation

as a critical strategic imperative to their company’s long-term success. However, when it

comes to describing their current state of adoption, 84 percent indicated they were in the relatively

early stages of the transformation. Companies’ needs will shift as they move up the

maturity curve, which has cultural implications because organizations will run in more agile

and collaborative ways.

Companies’ views on digital maturity & strategic importance

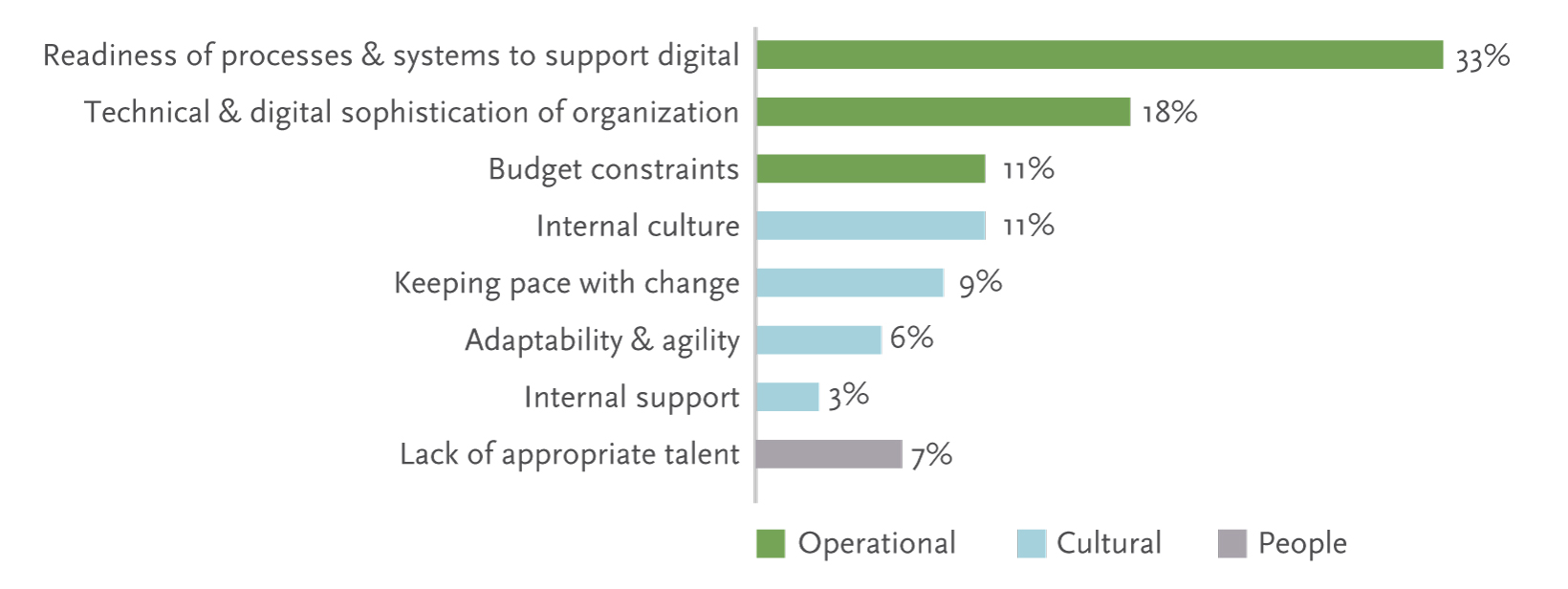

Overcoming obstacles

Beginning a digital journey and aligning the organization behind a digital strategy can be daunting.

Some 33 percent of survey respondents said the readiness of business processes/systems

to support digital was their biggest obstacle, up from 30 percent in 2016. Other impediments

include: the technical and digital sophistication of the organization (18 percent), internal culture

(11 percent) and budget constraints (11 percent).

Obstacles to digital transformation

By nature, many industrial companies are process-oriented and data-driven. But the level of

cross-functional collaboration required to successfully implement a digital strategy is new

territory for most industrial companies. Cultural attributes such as agility, flexibility, creativity

and innovation will be crucial in this Industry 4.0 world, according to those leading the transformational

change. Some of these cultural attributes are not indigenous to the sector, and

companies may need to look externally for talent. It then becomes the responsibility of the

company to evolve its culture to a point where external talent can succeed in the long term.

Cultural transformation

Survey responses suggest that organizations will find it necessary to shift their cultures to

support digital transformation. The best culture for a company is one that enables and accelerates

the mission and strategy of the organization, and allows it to respond effectively to

external challenges. There are no right or wrong answers when it comes to culture, as long as

they meet this criteria. As Lou Gerstner is famously quoted as saying, “Culture is everything”

when it comes to implementing successful strategies.

Using the Spencer Stuart culture model, we have found that many traditional industrial

company cultures sit in the lower half of this model, as they’re very results- and

process-oriented in order to deliver

stable, predictable performance. But

often, the talent associated with digital

innovation is more accustomed to environments

that fall within the top half of

the model, which are focused on flexible,

agile learning with a sense of

purpose, speed and collaborative decision-

making (e.g., Apple and Tesla).

The challenge for industrial companies

is to find the right balance between

delivering consistent profitable growth

and disruptive innovation. This appears

to be one of the biggest challenges

facing industrial leaders today.

Finding leaders to direct digital transformation

Driving a digital transformation starts at the top of an organization, but finding the right leaders

isn’t easy. Indeed, the biggest obstacle many companies will face is finding the leadership that

has the right skills to drive the transformation.

When asked “What capabilities do senior leaders need to drive digital transformation?” the

most common responses were: cross-functional influence and orchestration (40 percent), a

customer-centric mindset (30 percent), comfort dealing with ambiguity, flexibility and adaptability

(29 percent), and strong, inspirational leadership (29 percent).

Top five skills needed in an era of digital transformation

- Cross-functional influence

- Customer orientation

- Comfort dealing with ambiguity, flexibility and adaptability

- Inspirational leadership

- Strong communication skills and commitment to transparency

A leader who is going to head a digital effort must be ready to wear many hats, coordinate workstreams

across functions and, perhaps, infuse talent into the organization with skills that are

not indigenous to the organization.

To address this need, industrial companies often create new digital leadership positions, including

global digital transformation leader, social and digital communications director, and director

of data analytics. Given that digital branches across many different disciplines and requires a high

level of cross-discipline coordination, it can be difficult to determine who should oversee these

new positions. In a growing number of organizations today, the chief technology officer oversees

digital transformation (37 percent, up from 24 percent in 2016), followed by the chief marketing

officer. Interestingly, the number of CEOs owning the effort increased from 8 percent in 2016 to

14 percent in 2017, indicating an increased importance in companies’ strategic agendas.

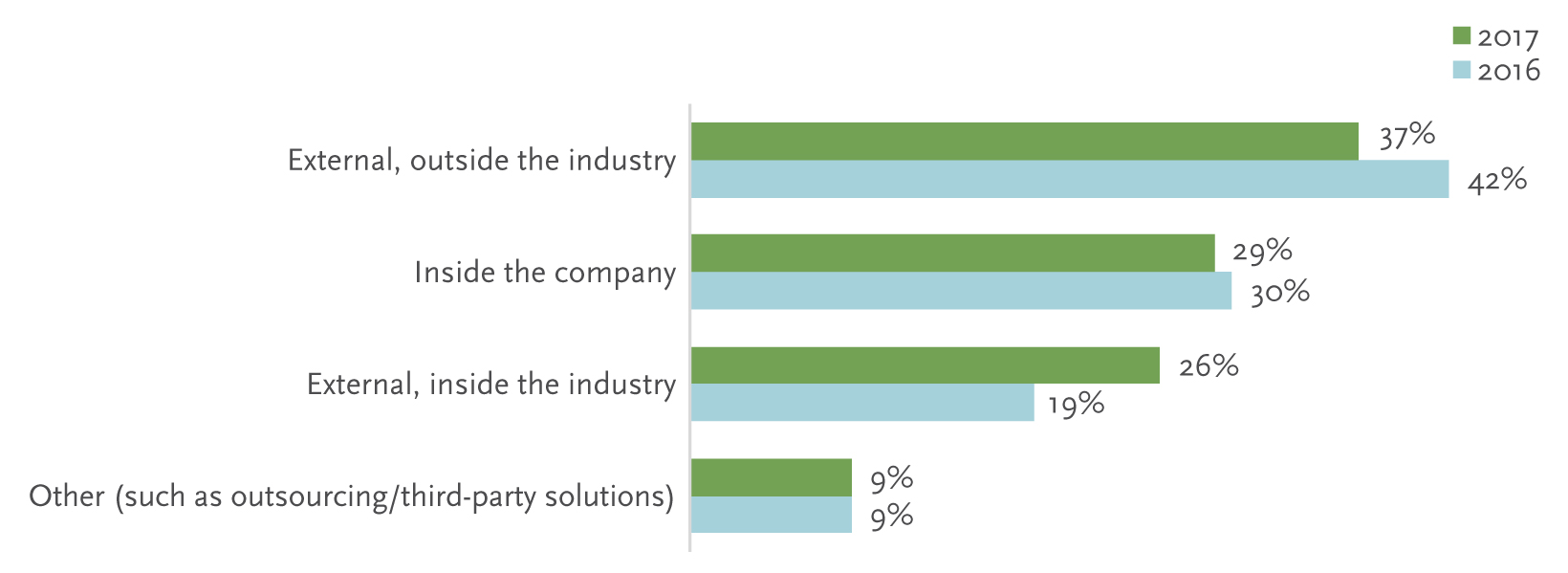

The majority of respondents (63 percent) said they are hiring externally for key digital roles, and

they are more likely to look outside the industry than within the sector for talent. The remaining

third are looking to fill these roles or develop individuals internally: “Legacy talent is typically

not adaptable to digital tools and mindsets,” one respondent noted. “There is a place for them,

but not on the front line of digital marketing.”

Where to find a digital leader

When hiring a leader to drive digital transformation, are you more likely to look inside the

industry or outside the industry for talent?

Best practices for success

Becoming digitally savvy requires organizations to inject new, broader perspectives into the

business, and to find talent with a wide-ranging, somewhat unorthodox skill set. As the importance

of digital accelerates, these efforts will be ongoing and continuous, as the associated

technologies continue to change and alter the landscape.

While the industrial sector is early in its digital journey, our respondents had a wealth of advice

to share with others on the same path. The advice we heard includes:

-

“Don’t give up, because the incorporation of digital, as a way of life, is imperative to

competing in the future.”

-

“Clearly communicate the strategy and the opportunity in front of you, so your organization

understands where you are headed and can support it on a cross-functional basis.”

-

“As with any change-management effort, benchmarking others, building alignment,

prioritizing objectives and establishing accountability are critical.”

-

“Identify collaborative and innovative leaders who can help the organization adopt new

behaviors and act with the sense of urgency required.”

With this advice, coupled with diligent executive sponsorship and focus, an organization

can pilot new digital ideas, “fail fast, fail forward,” invest for the long term and continue to

evolve as the digital landscape itself evolves. Digital transformation of the industrial sector

will take time, patience and an unprecedented level of collaboration. Is your organization

ready for this challenge?

* "What’s new with the Internet of Things?," McKinsey Global Institute, June 2017.